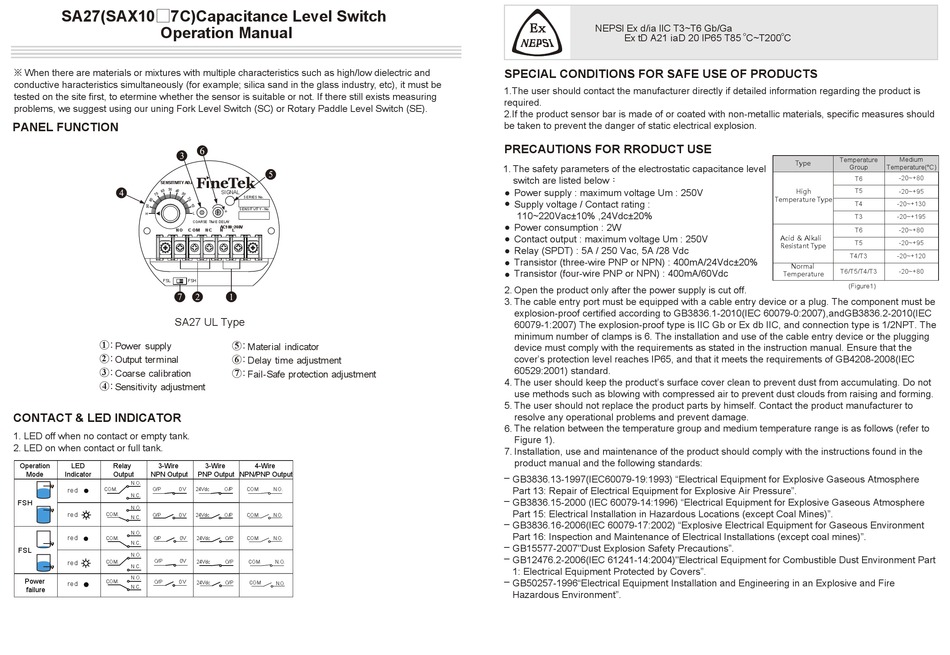

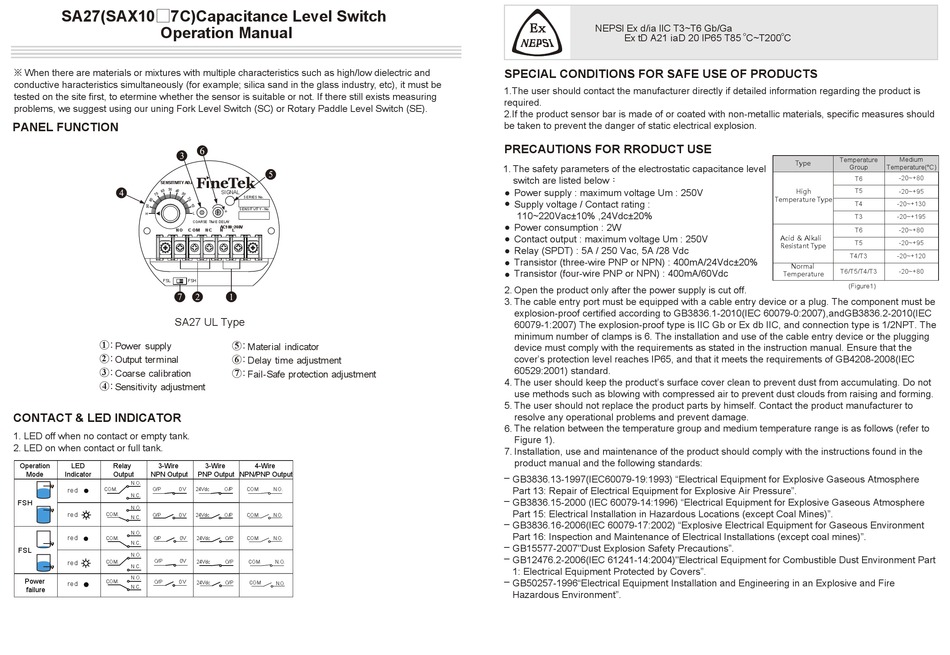

4 in turn-off failsafe high or maximum & when the sensor is installed for low level keep the DIP switch no. When the sensor is installed for high level keep the DIP switch no. Fail safe can be set via DIP switch No.4.ON the DIP switch No.3 and fill the material you can see LSV wait for 5 sec and after 5 sec it generate switching. On the DIP switch No.2 and empty the material you can see LSV wait for 5 sec and after 5 sec it generate switching. You can set the sensitivity through DIP switch No.1.

Relay status also change from NC to NO. You can see the status LED of LSV is on means material reaches to the high level. Now we fill the material solids, granuals or powder up-to the fork tines level. Power LED is on and status LED is in OFF condition. Trumen vibrating fork level sensor (LSV) starts vibrating in air. Also, when the fork comes in contact with a material, the vibration is dampened and the switch changes state. The Level Switch incorporates a piezoelectric crystal that vibrates the fork at its natural frequency. Connect the power supply either 15 to 80VDC or 15 to 260VAC on terminal 1 & 2 The Tuning Fork Level Switch is an ideal choice for level control of powders. Means if we are using sensor for high level we should keep this switch OFF.Īnd if we are using sensor for low level we should keep this switch ON. 4 is to set failsafe means the instruments should be in alarm condition if the sensor facess power failure. 3 is to set wet delay means on delay, sensor will wait for 5sec. 2 is to set dry delay means off delay, sensor will wait for 5 sec. Keep it turned-off for normal density (more than 200gm/litre) materials. 1 in this condition LSV will sense the material. There are 4 DIP Switches provided on connection panel Via DIP switch 1 we can set the sensitivity that means if the material is fluffy in nature or having low bulk density (less than 200gm/litre) we need to ON switch no. Terminal 4, 5, 6 & 7,8,9 are for relay output. Terminal 1, 2 & 3 are for auxiliary power supply. Open the cover of Trumen LSV you can see there are 9 terminals. In addition, the sensor is suitable for all kinds of applications for which until now several types of instruments were needed.Device operation and settings:Trumen vibrating fork level switch is very easy to operate. Against other methods of measurement as a fork of vibration, Ultrasonic sensors, the optical or just flotation buoys, this technology presents decisive advantages: it does not have vibration parts, it is insensitive to changes based on the conductivity, the temperature or pressure and especially fits very easily its sensitivity to discern between different media or products. Even difficult substances such as polyamide powder or paper are recognized in an effective manner. The high sensitivity across a range of measurement for dielectric constants of 1.5 up to 100 can detect all types of powders, granulates and liquids level. In contact with a medium with a dielectric constant different from the default it causes an electrical signal.

Relay status also change from NC to NO. You can see the status LED of LSV is on means material reaches to the high level. Now we fill the material solids, granuals or powder up-to the fork tines level. Power LED is on and status LED is in OFF condition. Trumen vibrating fork level sensor (LSV) starts vibrating in air. Also, when the fork comes in contact with a material, the vibration is dampened and the switch changes state. The Level Switch incorporates a piezoelectric crystal that vibrates the fork at its natural frequency. Connect the power supply either 15 to 80VDC or 15 to 260VAC on terminal 1 & 2 The Tuning Fork Level Switch is an ideal choice for level control of powders. Means if we are using sensor for high level we should keep this switch OFF.Īnd if we are using sensor for low level we should keep this switch ON. 4 is to set failsafe means the instruments should be in alarm condition if the sensor facess power failure. 3 is to set wet delay means on delay, sensor will wait for 5sec. 2 is to set dry delay means off delay, sensor will wait for 5 sec. Keep it turned-off for normal density (more than 200gm/litre) materials. 1 in this condition LSV will sense the material. There are 4 DIP Switches provided on connection panel Via DIP switch 1 we can set the sensitivity that means if the material is fluffy in nature or having low bulk density (less than 200gm/litre) we need to ON switch no. Terminal 4, 5, 6 & 7,8,9 are for relay output. Terminal 1, 2 & 3 are for auxiliary power supply. Open the cover of Trumen LSV you can see there are 9 terminals. In addition, the sensor is suitable for all kinds of applications for which until now several types of instruments were needed.Device operation and settings:Trumen vibrating fork level switch is very easy to operate. Against other methods of measurement as a fork of vibration, Ultrasonic sensors, the optical or just flotation buoys, this technology presents decisive advantages: it does not have vibration parts, it is insensitive to changes based on the conductivity, the temperature or pressure and especially fits very easily its sensitivity to discern between different media or products. Even difficult substances such as polyamide powder or paper are recognized in an effective manner. The high sensitivity across a range of measurement for dielectric constants of 1.5 up to 100 can detect all types of powders, granulates and liquids level. In contact with a medium with a dielectric constant different from the default it causes an electrical signal.

It is based on the technology of microwave and its deviation of frequency, which means that the frequency sent by the sensor experiences a change of the phase depending on the particular environment. The new Baumer LBFS level switch covers that gap. Until now it was hardly possible to cover all types of applications with a single level switch. Even the specific weight of the means to measure may limit the areas of application of the vibration fork, since, for example, resistance of very light media such as the ash may be so small that forks are unable to detect if you want to the environment. Vibrating level switches need also a lot of space outside the container. Longer the fork more prone to suffer mechanical damage and cambering are.

As the forks of vibration is introduced, depending on the version, between five and ten centimeters in the middle are difficult to clean. This also often produces errors of measurement because the sticky media are attached to the fork. The tuning fork level switch mainly uses the tuning fork resonance principle to measure the level status. The most common vibrating level switches have a fork of big vibration that enters the environment to measure the change in frequency of the same, which turns the output of the sensor. Even the mechanical composition of a sensor can lead to deficiencies. Often the area of application of level switches is limited because only they can be placed in certain positions in the container or because their little or excessive sensitivity leads to errors of measurement of some media.

0 kommentar(er)

0 kommentar(er)